Environmental responsibility

Environmental responsibility is a central part of Herrfors’ operations.

We are committed to long-term investments in renewable energy production and more efficient use of resources. Already today, a large share of our electricity production comes from renewable energy sources, and we continue to reduce the use of fossil fuels. Through investments in new technology and continuous improvements in energy efficiency, we are reducing our emissions and our environmental impact.

Electricity production

Herrfors’ electricity production is a mix of various energy sources, including wind power, hydropower, biomass, solar energy and nuclear power, as well as, to a lesser extent, peat, coal, and waste-derived fuels. We generate electricity in both our own and partially owned power plants.

For several years, Herrfors has been investing millions in new renewable electricity production, while also improving and optimizing our existing production resources to reduce carbon dioxide emissions.

In the summer of 2025, we commissioned a battery energy storage system of 6.7 MW/MWh in Oravais. The battery will participate in Fingrid’s reserve markets and contribute to balancing the power system.

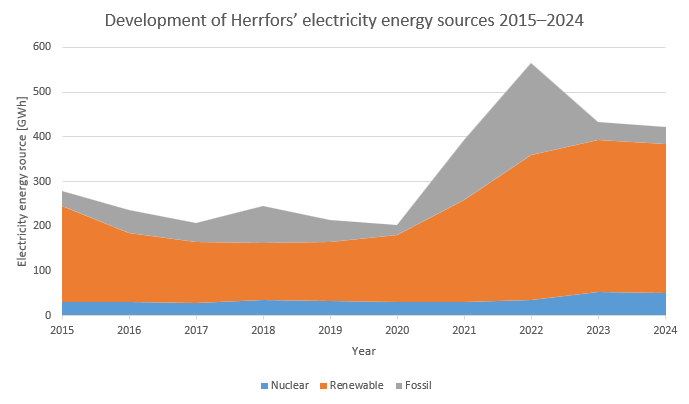

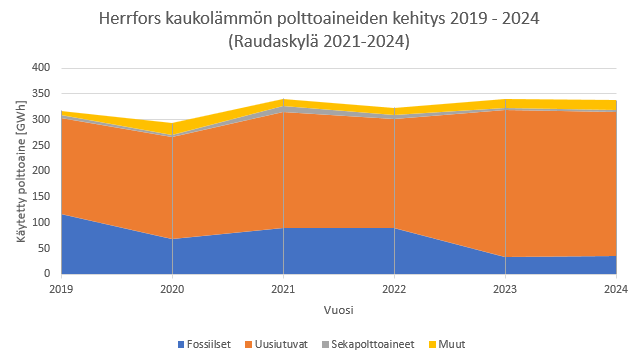

Thanks to long-term strategic investments in fossil-free electricity production, the fossil-free share of our production portfolio has now reached 91% (as of 2025). Our goal is to reduce the fossil share of our electricity production to below 5% by the end of 2025. The downward trend is illustrated in the graph on the left, showing a significant decline in the share of fossil-based primary energy sources in recent years.

During the energy crisis in 2022, Alholmens Kraft’s AK2 operated at high capacity, and peat was used to ensure a reliable electricity supply. As a result, fossil fuels were used to a greater extent than in other years.

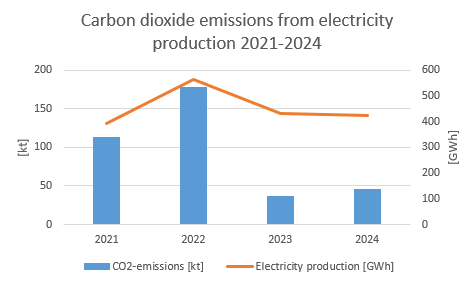

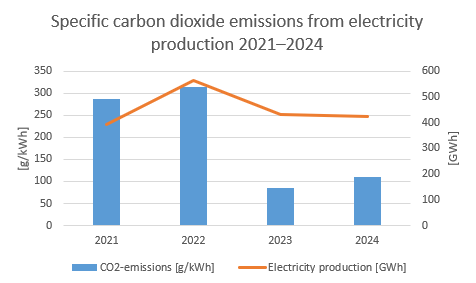

The development of carbon dioxide emissions from electricity production, along with specific CO₂ emissions, is shown in the illustrations covering a four-year period. The data highlight a substantial reduction in emissions: at their highest, in 2022, total CO₂ emissions were 178 kilotonnes, with specific emissions at 315 g/kWh. By 2024, these figures had dropped to 46 kilotonnes and 110 g/kWh, respectively.

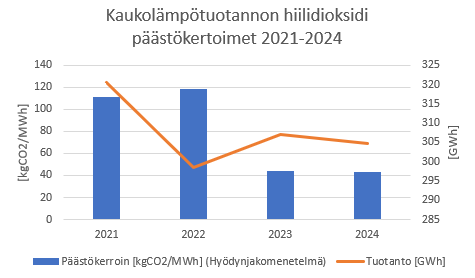

District heating production

In Pietarsaari, district heating is primarily produced by Alholmens Kraft. When needed, heat can also be produced via Herrfors’ own backup heating plants. The main fuels used are biofuels, such as bark, forest chips and other wood processing by-products, as well as peat.

In Ylivieska, district heating is produced at Oy Perhonjoki Ab’s own Vieskan Voima power plant. The plant is an energy-efficient combined heat and power (CHP) facility. It also includes a grate boiler that produces district heating during the summer and can support production during cold winter days. In case of operational disruptions, light fuel oil boilers can be used. Vieskan Voima uses forest chips, wood shavings, bark and a small amount of peat. The grate boiler operates exclusively on wood-based fuels. Each year, we conduct a sustainability assessment of the biofuels used in our production. In October 2024, Herrfors also commissioned a new electric boiler facility, which allows us to produce district heating using electricity, thereby reducing the share of combustible fuels. The electric boiler participates in Fingrid’s reserve markets and contributes to balancing the power system.

The trend in the reduction of fossil fuels is illustrated in the graph on the right, showing a significant decrease in the fossil share of primary energy sources in recent years. In 2024, 83% of the primary energy sources for district heating came from renewable sources.

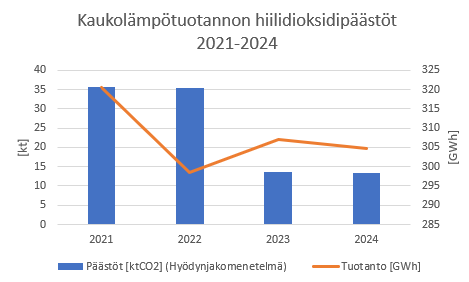

The development of carbon dioxide emissions and specific CO₂ emissions in district heating production is illustrated over a four-year period, showing a clear decline. At their peak in 2022, CO₂ emissions were 35 kilotonnes, and specific CO₂ emission coefficients were 119 g/kWh. By 2024, these figures had fallen to 13 kilotonnes and 44 g/kWh, respectively. The reduction is mainly due to the decrease in fossil fuels such as peat and coal.

We calculate the specific CO₂ emissions from our district heating production annually and publish the results on the KL-päästölaskuri website, maintained by Finnish Energy (Energiindustrin). There, you can check the fuel mix and see the carbon emissions caused by your district heating usage.

Material recycling

In the construction and maintenance of the electricity grid, district heating systems and production facilities, we carefully consider our choice of materials. Metals, electronics, plastics, and other waste materials are accurately sorted and sent to recycling facilities.

We continuously work to reduce the amount of residual waste and follow all applicable regulations and procedures for waste management to ensure that materials are handled in a safe and environmentally responsible way. In doing so, we take responsibility for the resources we use and for what we leave behind.

Energy efficiency

Herrfors is part of the national energy efficiency agreement and actively works to reduce energy consumption within our operations.

Through annual reviews and investments in the district heating network, we continuously identify opportunities for improvement.

Energy efficiency is a key component in reducing our environmental impact and using resources wisely both today and for the future.

Origin of sold electricity

If you have an electricity contract with Herrfors, it’s easy to find out the carbon emissions associated with your agreement. The origin and carbon dioxide emissions of the electricity we sell are calculated annually and published on our website. If you’re interested in renewable electricity, we also offer that as an option.